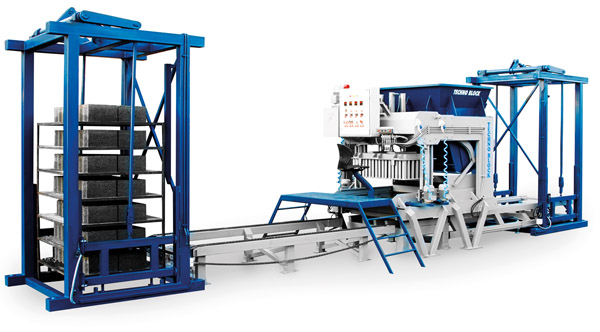

TB.E29 STATIONARY BLOCK MAKING MACHINE ON LEGGED METAL PALLETS

SPECIFICATIONS

Gross Weight & Overall Dimensions: 7,000 kg – 40.2 x 12 x 6 m

Power Supply: 220-380 V, 3 Phases

Hydraulic System with Five Hand Levers: Feeding & Loading the blocks/Pressing the blocks/Unloading the blocks/Opening & Closing the silo lid/Moving the blocks

Feeding Silo/Container: 1,100 L silo for the depot of the material, equipped with a hydraulic cylinder for opening & closing

Vibrators: Four 300kgf vibrators driven by four electric motors tot. 8kW to press the material into the moulds.

Pressing: One hydraulic cylinder with a hydraulic oil tank and a 7.5 kW electric motor to press the material, simultaneously with vibrators

Equipped with two Automatic Pallet Collector with a dedicated oil tank and two electric motors tot. 8 kW

Four meters long chain belt for shifting the pallets to robots with a 2 kW electric motor

Three-Phases control panel to operate and control the components

Production of various types of CMU blocks

Equipped with a 130L oil cooling radiator

Changeable mould

Production Rate: 1200-1400 blocks/h