TB.M55 STATIONARY MULTI LAYER BLOCK MAKING MACHINE ON WOOD PALLETS

SPECIFICATIONS

Pallet Layer Cage: For 15 pallets with dimensions of 115x90x4 cm

Pallet Layer: 4.5 meters long, with independent hydraulic cylinder & pump, it automatically inserts pallets beneath the mould.

Feeder Containers/Silos: A pair of 1cbm containers with separate body vibrators of 0.38kW and hydraulic open/close system for depot of normal & color concrete.

Hopper: 10.5m long, 4.5m high & 1,100kg displacement mobile hopper consists of a winch, pulleys, hanks, a 3kW electric motor, independent hydraulic pump & valves and a 45L oil tank. It carries the ready concrete into the silos.

Vibrators: Tot. 6 x 500kgf vibrators on the top & at the bottom of the mould, driven by 6 electric motors of tot. 26kW, which helps the mixture slips down into the mould.

Pressing: A pair of hydraulic cylinders with an independent pump which perfectly press the mixture along with the vibrators.

Two hydraulic rakes to convey materials from feeder containers onto the moulds.

Two separate material grinders with two hydro motors of 100cc power.

A 490L oil tank, two electric motors of tot. 14kW, ten hydraulic solenoid valves, pressure regulators & a 130L oil cooling radiator

Five independent hydraulic pumps with outflow rate of 70L/Mi10)

Automatic & Manual Control Panel

Power Supply: 220-380V, 3 Phases 100 A

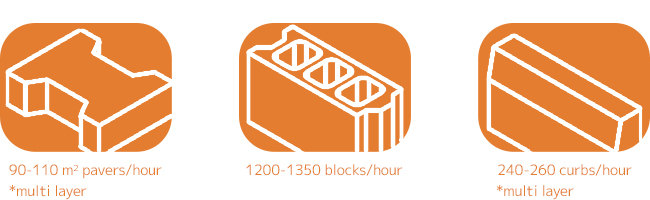

Production Rate: 240-260 curbs/h , 1200-1350 blocks/h ,90-110 sqm of pavement/h

Production of various types of concrete products (blocks, curbs, pavements …) single & double layer.