TB.M53 STATIONARY SINGLE LAYER BLOCK MAKING MACHINE ON WOOD PALLETS

SPECIFICATIONS

Pallet Layer Cage: For 15 pallets with dimensions of 115x90x4 cm

Pallet Layer: 4.5 meters long, with independent hydraulic cylinder & pump, it automatically inserts pallets beneath the mould.

Feeder Containers/Silos: A 1cbm container with 0.38kW body vibrator and hydraulic open/close system for depot of the material.

Hopper: 10.5m long, 4.5m high & 1,100kg displacement mobile hopper consists of a winch, pulleys, hanks, a 3kW electric motor, independent hydraulic pump & valves and a 45L oil tank. It carries the ready concrete into the silos.

Vibrators: Tot. 6 x 500kgf vibrators on the top & at the bottom of the mould, driven by 6 electric motors of tot. 26kW, which helps the mixture slips down into the mould.

Pressing: A pair of hydraulic cylinders with an independent pump which perfectly press the mixture along with the vibrators.

A hydraulic rake to convey material from feeder container onto the moulds.

A material grinder with a 100cc hydro motor.

A 490L oil tank, two electric motors of tot. 14kW, ten hydraulic solenoid valves, pressure regulators & a 130L oil cooling radiator

Five independent hydraulic pumps with outflow rate of 70L/Min?10)

Automatic & Manual Control Panel

Power Supply: 220-380V, 3 Phases 100 A

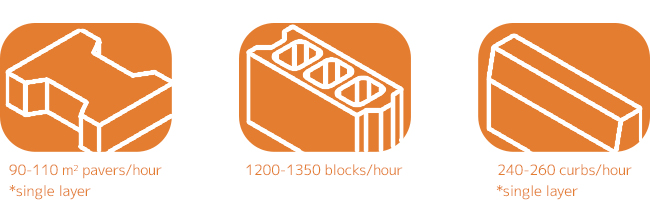

Production Rate: 240-260 curbs/h , 1200-1350 blocks/h ,90-110 sqm of pavement/h

Production of various types of concrete products (blocks, curbs, pavements …) single layer.